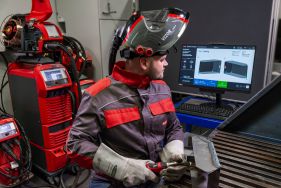

The documentation and analysis of process data are becoming increasingly important in welding technology. The Fronius range includes the following products:

WeldCube: A documentation and data analysis system that also connects multiple welding machines and enables accurate and continuous quality assurance and the evaluation of numerous welding parameters, thereby facilitating the optimization of manufacturing performance and reliability.

WeldCube Premium: Minimal administration and maximum overview. Increased transparency and productivity are achieved with WeldCube Premium software as part of the WeldCube portfolio. WeldCube Premium stores welding data from multiple systems in a central database and also offers intelligent management, statistics, and analysis functions. As such, the system allows the documentation of component-related data and the creation of PDF reports.

WeldCube Navigator: Real-time feedback solution for welding professionals. Faulty welded joints in the production process can result in massive costs and have a negative impact on overall productivity and quality. The WeldCube Navigator software solution supports you step-by-step in the manufacturing process. WeldCube Navigator combines two functions in one tool: the sequencer guides the welding specialist visually through the work process one step at a time, with the necessary instructions being created digitally in the Editor. A visualization of the work steps and the pre-setting of the defined welding parameters offer maximum support and so minimize the risk of error.

WeldCube Air: Our cloud-based software solution for companies of all sizes. Users not only have the option of managing their welding machines connected via the Internet, but also receive an overview of welding procedure specifications, qualifications, and the most important welding key figures. All this makes WeldCube Air the perfect companion to help welding companies go digital.

Fronius offers an extensive range of products and solutions in the field of robotic welding, from the welding machine and a wide variety of robot welding torches to intelligent assistance systems that boost quality and efficiency. As a system provider in the welding automation segment, Fronius implements customized, highly cost effective complete solutions for automated mechanized arc welding.

TPS/i Push systems: Push systems are particularly suitable for standard applications (e.g., CrNi and steel) where consistent quality and high system availability are required.

TPS/i PushPull systems: Equipped with two perfectly synchronized wirefeeders, these systems are mainly used for long wirefeeding distances and soft filler metals. PushPull systems are suitable for all processes and applications.

TPS/i CMT Twin: A combination of two independently operating forms of arc welding in a single process, be it two CMT processes or one CMT and one GMAW pulse welding process. Thanks to the extremely stable arc, even thin sheets can be welded at high speed, with little spatter, deep penetration, and an optimized weld seam flow.

LaserHybrid: A combination of laser and GMAW welding. The high welding speed and concentrated energy of the laser in combination with the GMAW arc bring advantages when joining thin sheets as well as thicker materials. LaserHybrid is now also available in combination with the TPS/i.

iWave automated—the versatile welding machine for every process: Discover the iWave, now for robot applications. This welding machine masters every welding process (TIG, plasma, MIG/MAG including all welding packages) with no compromises on quality. Whether you’re working with TIG or plasma, the iWave can be set up in both a hot wire and a PushPull configuration. Another highlight is ArcTig, a TIG keyhole welding process that stands out for its high welding speed and depth, which is now also available on the iWave platform.

Robot welding torch: With various torch bodies on offer in a range of lengths and with different angles, the right robot welding torch is available whatever the welding application. All robot welding torches are also available as gas and water-cooled versions.

Robot assistance systems: Save money with wire-based assistance systems

WireSense—detect the edge position and air gap height: The patented WireSense technology works together with the welding machine to enable the robot to detect the edge position and any air gaps between the sheets.

TouchSense—detect the fillet weld position: To compensate for component and clamping tolerances, the robot can use TouchSense to check the position of fillet welds automatically before each weld.

SeamTracking—track seams during welding: Where thick sheets or long seams are being welded, the resulting heat can lead to distortion or poor positioning of the components. SeamTracking ensures the detection of fillet welds and butt welds without any additional hardware whatsoever.

TeachMode—efficient robot programming: The teach mode supports the welder when programming welding positions on the robot and in doing so makes the programming process more efficient. The reversing wire movement prevents the wire bending upon unwanted contact with the component.

Robacta CTC: Robacta CTC automates the manual changing of gas nozzles. It takes no more than 50 seconds for the tip to be changed, without production being halted for someone to intervene. Pre-defined torques also reduce the risk of operating errors by maintenance personnel, thus extending the service life of the equipment.

Robacta Reamer: With the right cleaning, the service life of welding torch wear parts can be increased many times over. Depending on the welding material and application, we offer suitable cleaning systems to match the right welding torches and wear parts; for example, cleaning methods such as milling, brushing, or magnetic cleaning are available for steel or aluminum applications.

FCW Smart: The perfect way to get started with mechanized welding of pipe-pipe and pipe-flange connections, as well as valve and bearing seats. Easy to operate and program, the FCW welding cell is also an intelligent response to the acute shortage of skilled welding specialists and stands out thanks to its versatility when using various welding processes.

CWC-D: The Fronius CWC-D cobot welding cell is all about cost effective welding—from small batch runs through to series production. The welding cell provides for maximum flexibility: one-station operation for large workpieces, or two-station operation to set up and weld in parallel. Programming is made easy using drag and drop, with no prior knowledge of robot programming required. The Fronius Pathfinder also offers the option of offline programming to avoid production downtimes.

CWC-mobile: The Fronius CWC-mobile provides for portability in cobot welding. Its compact design, including the transport unit with casters and retractable feet, makes it easy to move the welding cell between different large components. CWC-mobile fulfills statutory safety requirements and is CE-certified. Not only that, the welding table makes it simple to weld small series.

Fronius Pathfinder: The Pathfinder programming and simulation software allows the user to create welding jobs offline without having to interrupt ongoing welding processes. This saves time and money. With the help of simulations, errors and collisions can be detected in advance and welding sequences optimized. Intelligent welding path management and innovative calibration logarithms guarantee accurate welding paths, which form the basis for high-quality welds that can be reproduced at any time.

HMI Cockpit: The innovative software solution for recording and analyzing machine data from automated Fronius welding systems. Increase machine availability, optimize your production processes, and analyze consumption and costs. HMI Cockpit makes welding work more efficient and reduces downtimes.

iSeamer: Fronius presents the new generation of welding systems for longitudinal seams—the iSeamer. Featuring a modular design, this longitudinal seam welding system boasts pioneering system control, innovative welding technology, and precision mechanical engineering.

Acerios—surface cleaning with hot active plasma: The Acerios hot active plasma technology allows partial and precise cleaning of material surfaces in industrial production by removing organic residues and film impurities without the use of chemical cleaning additives.

Fronius Additive: The additive manufacturing process for metal 3D printing, also known as wire arc additive manufacturing (WAAM), enables quick, cost effective, and precise component production. The wire-based and arc-based CMT process creates complex geometries and a high degree of flexibility in component design while delivering high deposition rates, all of which make Fronius Additive ideal especially for prototype construction and small batches.

Prototyping & Manufacturing Center: Our experts support you from the initial consultation through to the development and production of your component. We work with you to develop and optimize welding processes for prototypes, series production, and custom solutions—and this even extends to complex geometries, new materials, and challenging jobs. Based on targeted analyses and test series, we ensure quality and efficiency and create cost effective, reproducible production processes.

Fronius offers ideal solutions for every manual welding process—MMA welding, MIG/MAG, and TIG and plasma welding, along with the right welding torches. The range includes:

TPS/i: MIG/MAG welding machine equipped with extensive communication features, also suitable for customization and retrofitting. Available in power categories 320 A, 400 A, 500 A, and 600 A, as well as 270 A and 320 A compact versions. Several function packages allow the use of different dip transfer and pulsed arc processes, including PMC (Pulse Multi Control), LSC (Low Spatter Control), and CMT (Cold Metal Transfer).

iWave—TIG DC and AC/DC: The iWave TIG welding machines offer top quality for every weld and every material. Available in power classes 190 A and 230 A for mobile use and 300 A, 400 A, and 500 A as a stationary TIG welding system. Designed for maximum modularity, these welding machines can be adapted precisely to customer requirements. There’s also the option to upgrade the iWave 300i-500i for plasma welding.

iWave—Multiprocess PRO: From TIG and plasma to MIG/MAG or MMA, the iWave 300i, 400i, or 500i devices with the Multiprocess PRO option also give access to all process variants from the MIG/MAG range in addition to the full range of high-tech TIG functions. The modular welding packages can be used to bring together the precise functions required for the welding process: Standard, Pulse, PMC, LSC, and CMT. You even have the option of professional manual metal arc welding—with all the benefits of cellulose electrode welding.

Artis: In TIG welding, the focus is entirely on achieving a high weld quality. In doing so, it is just as important to maintain a stable arc at all times as it is to have a wide range of functions on the welding machine. The Artis TIG DC generation of devices masters this balancing act perfectly, combining both in a compact, robust system design. Plus, Artis offers all the key setting options that are otherwise found only on larger professional TIG DC systems.

Ignis: Ignis is a compact line of MMA products that offers the perfect weld every time, even under the most adverse conditions, in the smallest of spaces, indoors or outdoors. The robust and durable housing can handle external influences such as dust and moisture without a problem. Pioneering technologies and numerous functions help get welding off to a smooth start and continue to offer support throughout the whole welding process. All this makes the Ignis the perfect companion—especially on construction sites, for repair and maintenance work in industry and agriculture, and in any home workshop.

TIG DynamicWire—active wire control for TIG cold-wire welding with iWave 300i-500i: The innovative advantage of Fronius TIG DynamicWire compared to conventional continuous wirefeeding in cold-wire systems lies in its automatic self-regulation. The welding machine actively adjusts the wire speed to the welding behavior, torch position, and current conditions. The system can even automatically compensate for component tolerances of up to 30%.

MIG/MAG welding torches: Unbeatable precision and service life: The MIG/MAG welding torches deliver the best outcomes in gas-cooled and water-cooled applications. Hosepacks up to 15 meters long and torch bodies of different lengths and angles make life easier for every welder, not to mention the remote control in the handle on certain models.

TIG welding torches: The modular design of the new TIG Multilock welding torches means they can be individually adapted to almost any customer requirement. Different torch body lengths, a range of torch cap sizes, and rotating torch bodies make it easier to access hard-to-reach places and ensure effortless handling.

FlexDrive: Are you looking to bridge larger distances between the welding machine and the welding point with ease? That’s no problem with the FlexDrive WF 25i—a small, portable intermediate drive between wirefeeder and welding torch.

WF 25i Dual for super-quick wire changes: As an extension for the TPS/i device series, the Dual Wire Feeder allows the user to quickly switch between two wire thicknesses or wire materials at the touch of a button.

MagicCleaner 150/300: The MagicCleaner 150/300 series represents an innovative technology for the treatment of TIG welds and stainless steel surfaces, facilitating the cleaning, polishing, and inscribing of stainless steel. In contrast to mechanical or chemical cleaning, the material surface is not affected by the process. No work-in time is required and an additional passivation process is no longer necessary.

Every welding application is accompanied by health hazards and it is our aim to provide every welder with appropriate, long-term protection against these risks. In addition to our extensive range of welding machines, we therefore also offer a variety of welding safety products, particularly in the areas of welding fume protection, UV and glare protection, as well as flame and heat protection.

Mobile welding fume extraction

Exento HighVac: The mobile high-vacuum extraction system is equipped with an extra-large, vertically mounted filter cartridge that delivers a thorough clean via the built-in semi-automatic filter cleaning system. Thanks to its particularly high filter quality, the Exento HighVac is EN ISO 21904-1, W3-certified. Intuitive single-button operation allows the welder to freely set the perfect extraction capacity. This setting remains consistent even with increasing filter saturation thanks to the integrated automatic volumetric flow control.

The Exento HighVac is a perfect counterpart to our Exento fume extraction torches and complies with the EN ISO 21904-1 standard.

Exento HighVac Duo

The new version of the Exento HighVac Duo (W3 certification pending) combines all the advantages of the familiar Exento HighVac but also offers simultaneous extraction at two workstations. Intuitive single-button operation makes the machine easy to use even when wearing gloves. The Exento HighVac Duo is the perfect counterpart to our Exento fume extraction torches, which are connected to the device via the two connectors (both NW45/63 mm).

Like the Exento HighVac single-user solution, the Duo version can also be equipped with useful options (e.g., automatic start-stop).

Exento LowVac: The Exento LowVac mobile low-vacuum extraction system provides users with effective protection against welding fumes and is extremely cost effective thanks to its long service life. It has a disposable filter with a surface area of 25 m² that can be replaced by an extra-large 42 m² disposable filter if required. The filter can be changed without contamination when saturated. Certified according to EN ISO 21904-1, W3, the device meets high quality standards.

Exento LowVac Clean

Based on the classic Exento LowVac model, the Exento LowVac Clean (W3 certification pending) also has an automatic filter cleaning system, so regular filter changes are no longer necessary.

Like the Exento LowVac, the Exento LowVac Clean can be equipped with optional extras (e.g., automatic start-stop, extraction hood with lighting, etc.).

Respiratory protection systems and automatic welding helmets

Vizor Air/3X respiratory protection system: Filtered air and a clear view come thanks to our Vizor Air/3X PAPR system, consisting of a powered air-purifying respirator, interconnecting hose, and carry strap. Combined with one of our matching welding helmets (e.g., Vizor Air/3X Connect, Vizor 4000 Air/3X Plus, or Vizor 4000 Air/3X Professional), the system filters up to 99.8% of welding fume particles out of the ambient air via a TH3P-R-SL particle filter (maximum classification). It then routes the cleaned air through the interconnecting hose and directly back into the inside of the welding helmet.

Vizor Crystal/Vizor Crystal Air: Featuring brightness level 2 when open, large field of vision (nose cut), and crystal-clear optics, the Vizor Crystal comes with state-of-the-art digital electronics (AutoShade, twilight function, multi-sensor detection, etc.) that form its own assistance system to optimally support the welding specialist.

Vizor 4000 Crystal/Vizor 4000 Crystal Air: Featuring brightness level 2 when open, the Vizor 4000 Crystal provides a crystal-clear color-realistic view even during the welding process. Thanks to autopilot, you also always enjoy the optimum level of protection.

Vizor Connect/Vizor Connect Air: When welding for 6 to 8 hours a day, a welder ignites the arc several hundred times. With each ignition, delays of fractions of a second arise before the automatic auto-darkening filter cartridge of the welding helmet closes, but not with the Vizor Connect. Thanks to Bluetooth® technology, the welding helmet darkens even before the arc ignites. Other highlights of the helmet include a panoramic view, autopilot, brightness level 2.5, shade level range 5-12, and much more.

Vizor 4000 Professional/Vizor 4000 Professional Air: This automatic welding helmet earns top marks when it comes to EN379 classification 1/1/1/1, a broad range of uses, perfect visibility, and the option to choose between autopilot and manual levels of protection, brightness level 4, and shade level range 5-13.

Vizor 4000 Plus/Vizor 4000 Plus Air: The automatic welding helmet impresses with true color display, adjustable angle by sensor slider, grinding mode, brightness level 2.5, and shade level range 8-12.

Fazor 1000 Plus: A welding helmet that combines robust quality with outstanding value for money. Further special features include brightness level 4 and shade level range 9-13.

In addition to these welding safety products, we also offer a wide range of protective clothing for welders (jackets, pants, aprons, gloves, and much more). In addition to the clothing, plug-in welding torch heat shields and button extensions also ensure even better heat protection during all welding tasks.

Ergonomics

In addition to the protection measures mentioned above, it is also necessary to consider ergonomics in welding, to support and protect the welder at work. This requires solutions not only to assure critical health and safety at work but also the necessary comfort when working, in order to promote a healthy musculoskeletal system.

We have focused here on solutions such as hosepack lengths of up to 15 meters, balanced welding torches, and torch bodies with different lengths and angles.

Welducation Simulator & Welducation Campus

The new Welducation Simulator takes virtual welder training to a completely new level. The simulator is integrated into the housing of a standard welding machine with real welding torches and super-realistic visuals thanks to augmented reality (AR). Using the simulator, welders can learn, train, and consolidate their welding skills step-by-step under realistic conditions without any risk to safety or material costs. The associated Welducation Campus platform allows welders to undergo comprehensive training with virtual tasks, theory, and course creation and management plus integrated knowledge checks.

Founded in 1945 as a regional specialist repair shop for radio and electrical equipment, Fronius has grown to become an essential player in the global industry over the past 80 years. Throughout its history, team spirit, perseverance, and staying power have always been at the heart of the Austrian family business.

It all started on June 20, 1945, when Günter Fronius officially advertised that he would be offering maintenance services for radio and electrical appliances out of a hotel. Not long after, the trained electrical engineer had a revolutionary idea: He built a device for recharging car batteries, allowing them to be used for longer. This first Fronius product was a big hit, and was followed by innovative chargers for industrial applications such as forklift batteries. The company’s success story had begun.

“If you look at the conditions at the time, our beginnings came down to innovative strength, boldness, and team spirit. Resources were in short supply, but that sparked my grandfather’s inventive spirit and drove him to make the best possible use of what he had to work with, to make it repairable and affordable for a broad sector of the population,” says Elisabeth Engelbrechtsmüller-Strauß, Fronius CEO and granddaughter of the company founder.

Success thanks to perseverance

Just five years in, Günter Fronius expanded the company’s range to include welding transformers. This move laid the groundwork for Fronius to grow into a substantial, medium-sized industrial company. In 1980 Günter Fronius handed over the reins to the next generation, Brigitte Strauß and Klaus Fronius. They launched a program of growth and international expansion that delivered innovative welding solutions and led to the founding of numerous subsidiaries all over the world—of which there are now 37. Starting in 1992 Fronius also turned its attention to solar energy, which was considered alternative at the time but is now indispensable in the energy industry.

“Renewable energy is a driving force for us, so we are continually working on solutions that link up the electricity, heating, cooling, and mobility sectors to achieve our vision of 24 hours of sun,” says Engelbrechtsmüller-Strauß, who took over the management of the company from her mother and uncle in 2012.

Success thanks to progress

Through its products and solutions, the technology company has helped to drive economic progress worldwide, thus contributing significantly to the growth of other companies, for example in the automotive industry. The 20th anniversary of Cold Metal Transfer (CMT) represents a key milestone in this context. By introducing this innovative welding process, Fronius ushered in a paradigm shift in welding technology. For the first time ever, CMT made it possible to thermally join galvanized steel and aluminum sheets, as well as joining wafer-thin aluminum sheets from a thickness of 0.3 millimeters.

Fronius currently operates in two strategic business areas.

Fronius Welding continues to revolutionize welding technology, while Solar & Energy is moving ever closer to its goal of making the best possible use of solar energy as well as optimizing battery charging systems for intralogistics—based on the idea of the company’s founder and the very first Fronius product. While these two lines of business may appear very different at first glance, the company’s team of 7,000 specialists worldwide continues to pursue the same clear mission, just as it has for the past 80 years: Researching and controlling electricity as the fuel of the future. “And we want to make this a future worth living—for us and future generations,” says Engelbrechtsmüller-Strauß.

Success thanks to foresight and vision

As well as looking back, the company’s anniversary is an occasion to think about the future. Fronius will continue to research ways of converting electrical current as well as developing, producing, and pushing forward with targeted solutions in this field. While the company is continually breaking new ground in this regard, the managing director notes that certain things are set in stone: “No one really knows what the future will bring. But we will remain financially independent and continue boosting Austria’s standing as a business location—and thus value creation for our products in Europe. Our drive to research will be part of everything we do, always focusing on quality and user-friendliness.”

Fronius International GmbH is an Austrian company with headquarters in Pettenbach and other sites in Wels, Thalheim, Steinhaus and Sattledt. With 7.000 employees worldwide, the company is active in the fields of welding technology, photovoltaics and battery charging technology. 89% of its products are exported through 36 international Fronius subsidiaries and sales partners/representatives in over 60 countries. With its innovative products and services and 1,366 granted patents, Fronius is the global innovation leader.

Plan your visit to the trade fair!